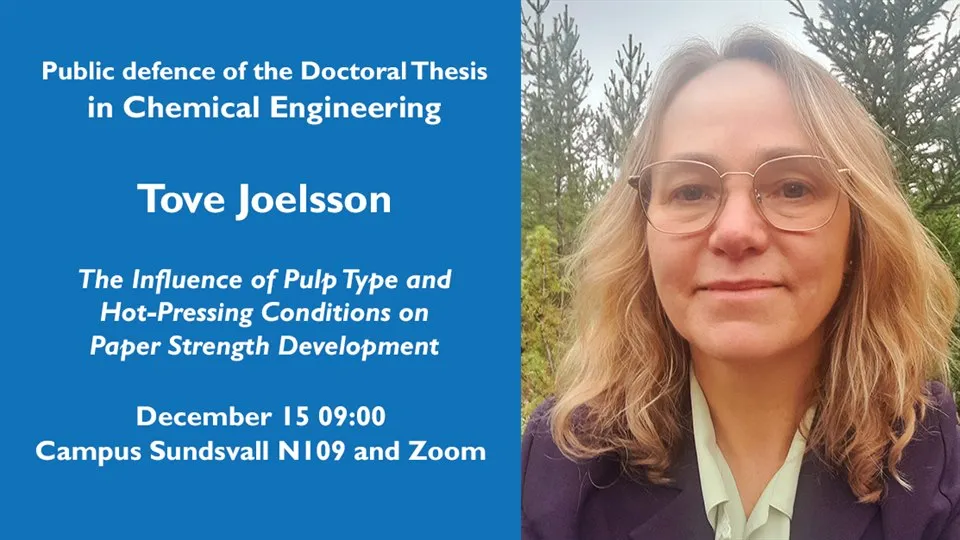

Disputation i kemiteknik

Välkommen till disputation i kemiteknik med Tove Joelsson. Tove är industridoktorand vid FSCN forskningscentrum, forskarskolan FORIC och Treesearch nätverket.

Disputationen hålls på campus Sundsvall i Fälldinsalen, N109 och digitalt via zoom.

Forskningen handlar om att utveckla teknik för varmpressning av högutbytesmassa för skogsindustrin. Varmpressningstekniken har visat sig ha potential för tillverkning av starka, våta stabila pappersmaterial baserade på miljövänlig förnybar och återvinningsbar lignocellulosa. Syftet med detta arbete var att studera hur massans egenskaper och varmpressningsförhållandena påverkar hållfasthetsegenskaper.

Resultaten visade att torrhållfastheten kan öka upp till 150 % för högutbytesmassa (HYP)-baserade ark vid pressningstemperaturer långt över ligninets mjukningstemperatur. Ökningen i torrhållfasthet var linjärt korrelerad med densitet upp till 200°C. Den maximala torra draghållfastheten som erhölls var 70 kNm/kg vid 200°C presstemperatur och motsvarande värde för en ligninrik kraftmassa var ca 130 kNm/kg, en ökning med 30 %. Den våta draghållfastheten för papper baserat på HYP ökar från 2 till 28 kNm/kg och för papper baserat på oblekt kraftmassa från 5 upp till 60 kNm/kg i temperaturintervallet 20-270°C. Ökningen i våtstyrka oberoende av massakvalitet verkade vara exponentiell för pressningstemperaturen med den brantaste lutningen över 150°C. Förhållandet våt/torrstyrka var cirka 35-60 % för alla ligninhaltiga massakvaliteter, vilket indikerar att en signifikant våtstyrka uppnåddes.

Avhandlingens titel

The influence of pulp type and hot-pressing conditions on paper strength development

Abstract

The hot-pressing technology has proven to have the potential for manufacturing of strong, wet stable materials based on eco-friendly renewable and recyclable lignocellulose. The purpose of this work was to study how the pulp characteristics and the hot-pressing conditions affect the dry and wet strength properties of paper.

The results showed that dry strength can increase up to 150% for high yield pulp (HYP) based sheets at pressing temperatures well above the softening temperature of lignin. The maximum dry tensile strength obtained was 70 kNm/kg at 200°C pressing temperature and the corresponding value for a lignin-rich kraft pulp was about 130 kNm/kg, an increase of 30%. The increase in dry strength was linearly correlated with density up to 200°C whereafter it levelled off and was reduced. The wet tensile strength for paper based on HYP increase from 2 to 28 kNm/kg and for paper based on unbleached kraft pulp from 5 up to 60 kNm/kg in the temperature interval 20-270°C. The increase in wet strength independently of pulp grade seemed to be exponential to the pressing temperature with the steepest slope above 150°C. For unbleached kraft pulp a lignin content of minimum 7% seemed to be necessary for improved wet strength but 12% gave the highest value within the studied interval. In HYPs the lignin content is 25-28% but the level of wet strength was lower which is probably related to the lower density and lower dry strength compared to unbleached kraft pulps. The sulphite treatment of wood chips in mechanical pulping softens the lignin in moist conditions and improves the fibre compressibility. It was observed that at 150°C temperature the dry strength increased by 15% to a level of 71 kNm/kg for high sulfonated pulp compared to lower sulfonated pulp that had a dry strength of 60 kNm/kg at the same density. The level of wet strength was however not found to be affected by the sulfonation. Paper strength is largely related to pulp fibre morphology and fines content. This was studied with respect to hot-pressing and the results indicated that the relative influence of fibre morphology seems to be reduced with increasing pressing temperature. Hot-pressed sheets based on a coarse fines free fibre fraction showed 100% dry strength increase and wet strength increase up to 20 kNm/kg. However, the dry and wet strength were shown to be favoured by the presence of fines fraction.

It was found that the ratio wet/dry strength was about 35-60% for all lignin containing pulp grades. A rule of thumb for an efficient wet strength resin is that the wet/dry paper strength ratios are 15%. The wet strength development as a function of temperature was fitted to an Arrhenius type of equation and activation energies were found to be similar for very different pulp grades provided that the lignin content is above 7%. This could indicate that the process(es) giving wet strength were similar.

Handledare

Professor Per Engstrand, FSCN forskningscentrum Mittuniversitetet

Opponent

Professor Tom Lindström, Innventia AB/KTH

Betygskommittée

Dr. Lars Johansson, Lead scientist, Fibre Technology and Application, RISE PFI, Trondheim

Professor Samuel Schabel, Technische Universität Darmstadt

Professor Monica Ek, KTH

Länk till zoom mötet

Hämta inbjudan som PDF

Hämta abstract som PDF

Länk till avhandlingen i DIVA